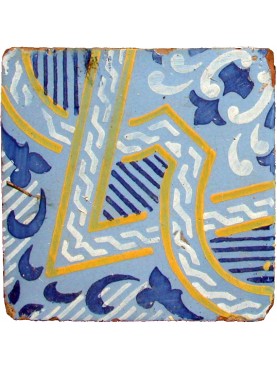

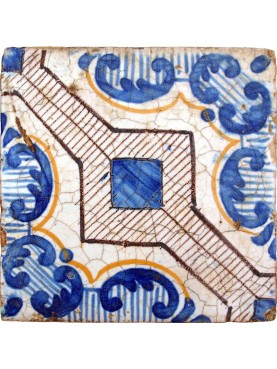

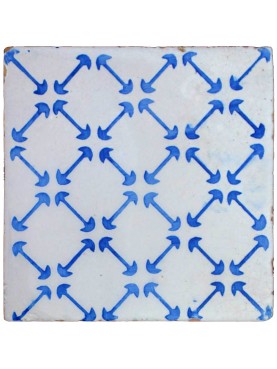

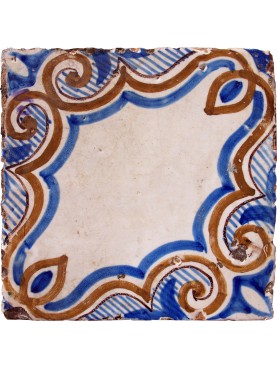

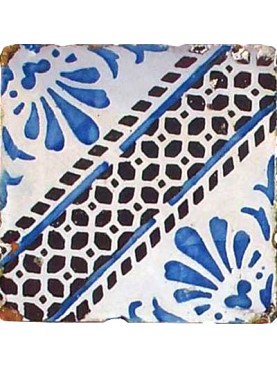

Sicilian Majolica ancient tile blue and white

Sicilian Majolica ancient tile blue and white

Original

Original, ancient tile with a light blue background and cobalt blue and white aluminum oxide designs.

Carmelo Gerbino factory in Santo Stefano di Camastra.

24 Available

Data sheet

| Height | 7.87 in | 20 cm |

| Width | 7.87 in | 20 cm |

| Thickness | 0.67 in | 1,7 cm |

| Weight | 2.87 lbs | 1.3 Kg |

| Ancient manufacturing source | Carmelo Gerbino 1874 | |

| Historical period | XIX century | |

| Manufacturing | Sicilian Carmelo Gerbino 1874 | |

| Material | Maiolica/Majolica | |

| Note 01 | Santo Stefano di Camastra (Messina) |

More info

The GERBINO Family .... in the midst of the Sicilian baroque epic, the Duke of Camastra he rebuilt the current site of S. Stefano di Camastra, restoring dignity to those artisans survivors of a catastrophic natural event that had the old farmhouse on his lands was destroyed. The territories of S. Stefano were very rich in materials clayey and with the ingenuity and wisdom acquired by the people and from the cultures that had dominated the territories in past centuries, these artisans took it upon themselves to exploit this resource passing down to us one of the most prestigious traditions of the land of Sicily. The "GERBINO family" was one of the first artisan workshops who knew how to set up various clay production workshops since the end of the 15th century, recognized for the prestige of the shapes and the particularity of the decorations. When Luigi Pirandello wrote his famous short story "The Jar" in 1900, it is very likely to think that he was referring to one of the many jars produced in the Gerbino family's furnaces, in which the land of Sicily is still transformed today, as if by mystical ritual, from inert matter into fine vases. The "Premiata Fabbrica di Carmelo Gerbino e Compagni", established in 1874, characterized by an oval brand with a star in the centre, was specialized in the production of high-quality majolica bricks. These are bricks that are carefully crafted in the creation of the biscuit, but also in the predominantly geometric decoration or with vegetal motifs, carried out with the aid of the template, and well defined individually by hand. An example is the beautiful flooring existing in Palazzo Trabia. Another company is that of "Salvatore Gerbino and sons", characterized by the oval brand with an anchor in the centre, probably born under the auspices of Don Gaetano Armao and due to kinship reasons. No less important are those headed by Rosario Piscitello and Biagio Franco, the Napoli, the Mazzeo; some examples made by these majolica makers are present in the Ceramics Museum and in the Old Cemetery, used in the two-year period 1878/1880. Text published in the catalog "Walking on the past" majolica terracotta tile from the 16th to the 20th century published by the Andrea Pantaleo Cultural Association - Monreale 1995 Courtesy The processing of clay for clay purposes is as ancient as the town of Santo Stefano di Camastra itself, the original one, prior to the disastrous landslide of 1682. The feudal lords Don Giuseppe Lanza and Barresi (1628-1708) Duke of Camastra and his wife Donna Maria Gomez de Silveyra, princess of Santo Stefano, wanting to rebuild the town, requested and obtained from the Spanish viceroy, the only representative of the crown in Sicily, the "licentia haedifìcandi" in a Plan of Castellacelo which they owned, rich in clay quarries. From 1683, the date of the granting of the license, and under the guidance of the prince, the farmers, transformed into builders, rebuilt the town over a period of twenty-three years. The plan of the historic centre, a rhombus inscribed in a square, was designed by the prince himself and presents similarities with the seventeenth-century layouts of the gardens of Versailles and the Royal Palace of Madrid. For the reconstruction work near the inhabited center, the so-called "stazzuni" were established near the clay quarries, of excellent quality, for the processing of building materials: tiles, bricks and "catusa", or terracotta cylinders. From that first phase we moved on to a more complex organization to produce bricks, vases, plates and crockery of various kinds. After the mid-18th century, in the wake of the rich lord Antonino Strazzeri, prince of S. Elia, master ceramists such as the Azzolina and Palermo from Caltagirone, the "maiolicari", Mazzeo and Tarallo from Barcellona, and other masters from Barcellona flocked to S. Stefano. from different places, mainly from nearby Patti, who gave their contribution of experience and work to the nascent local factories. Commercial exchanges with the "Vietri" masters, the Pizzicara, allowed the potters of Santo Stefano to learn and perfect the tile covering technique. Since the 18th century, the production of majolica tiles has been flourishing and appreciated, exported throughout the south and also requested by Caltagirone and Palermo, well-known ceramic centres, for the renovation of floors worn out by use. The creation of majolica tiles required better organization of the workshops which needed various specialized workers. The "turrazzara stampatura", so called from the locality "Torrazzi", near the clay quarries, called "stazzunara", dug the clay and had the task of molding, that is, pressing the clay into wooden boxes of 22 cm and possibly imprint the name of the client factory with a bronze mark. As the clay dried it was reduced and the "printed" brick reached the traditional measurement of cm. 20 x 20. Once dried, the bricks were cooked in wood-fired ovens and around a thousand bundles of wood were used for cooking: this operation required the work of the so-called "infurnaturi", specialized in arranging the bricks inside the oven using the "ritagghia", or clay scraps, to prevent them from touching each other during cooking, as well as the "seams" to control the fire which had to maintain a constant heat. The firing operation lasted approximately twenty hours and the cooling operation forty-eight, a longer time than that required for other ceramic objects. The transport of the bricks was carried out by the women who managed to transport up to thirty bricks at a time from the "Turrazzi" district to the embarkation points at sea or to the shops in the town, with a piece of cloth twisted around their heads or "cruna". Here the bricks were decorated using mask molds consisting of heavy cardboard soaked in linseed oil, which once dry, became rigid and waterproof, were perforated according to a pre-established design in which a different mask had to be used for each colour. The most used were ramina green, yellow, cobalt blue, red and manganese, almost always on white enamel, but at the end of the 19th century colored enamels were used, especially blue and yellow. The price increased depending on the quantity of molds used. After the decoration, the second firing was carried out, following the procedure also used in the first. It is precisely in the 19th century that, while keeping the acquired and experienced artisan tradition alive, we witness the transformation of the production technique from artisanal to industrial. The increased demand for majolica tiles stimulates ceramic workshops to produce more, better and in shorter times. The repertoire of decorations is not very vast at first. The designs are simple, generally in white and blue with the addition of some other sponged or marbled colors. Each decoration is given a name: "rococo", "five points", "rigatino", "lancetta": later the decorations become more numerous and richer, as the local ceramists became aware of Neapolitan ceramics. The brothers "Liborio and Gaetano Armao di Michelangelo" in the first half of the 19th century, while continuing according to tradition to produce pottery for domestic use, specialized in the production of tinned tiles and to improve their quality they were concerned with perfecting the "biscuit" technique ", creating compact and resistant bricks like the Neapolitan ones, even if of unusual sizes for S. Stefano: in fact they go from the traditional size of 20 x 20 cm to approximately 21 x 21 and a thickness of 2.5 cm. To also improve the painting technique, the Armaos called French ceramists to S. Stefano who stayed for several years to work for them. By improving the quality of the colors and the tin glaze which takes on greater brightness during firing, bricks are produced which stand out for their refinement and chromatic liveliness, and for the refinement and sobriety of the decorative motifs. While taking into account the ceramic tradition typical of Santo Stefano, French motifs present in eighteenth-century porcelain which only use cobalt blue on white are also introduced. The decoration is generally completed on four or eight bricks and although the template is used to facilitate processing, they are finished by hand individually, with the addition of borders and touches of colour. The bricks produced in the second half of the 19th century, although still presenting a lively decoration, are more standardized and smaller in size. 20 x 20 with a thickness of 2 cm. At the end of the nineteenth century the measurements were further reduced to cm. 19 x 19 with a thickness of 1.7 cm; the decoration takes place inside the single brick which is devoid of originality; the enamel becomes opaque and the characteristics of refinement that had distinguished the Armao factories are lost. At the Turin Exhibition of 1884 the Armao company was present with vases and "valuable floor samples"; at the Messina Exhibition he obtained a bronze medal and another at the Palermo National Exhibition of 1891-92 for the production of tiles. The Armao brands undergo variations with the succession of different generations of the family. The original one consists of an oval or a rectangle with the inscription "Fabbrica Premiata Fratelli Armao - Santo Stefano di Camastra", or of a frame with scrolls and vegetal motifs with the above inscription. At the beginning of the 20th century the brand was simply an oval with the inscription "Giuseppe Armao e Figli". The last owners of the factory, having no direct heirs, sold the company to the Mazzeo family with whom they were related (this factory no longer exists today).